KK Introduces Innovative Manhole Covers

01-07-2010

In our 25 years experience of making precast concrete manhole covers and frames, we have realized that the current IS code has failed to meet some of the primary functions for which it was designed.The IS code for Heavy Duty covers provides for 2mm thick mild steel sheet around the periphery of the cover and two mild steel lifting hooks placed about 2 to 3 inches away from the extreme edge of the cover. It also provides for a gap of 5mm around the cover between the cover and the frame besides a test load of 20 MT for failure.All the above specifications except the test load have miserably failed to provide a cover which can be opened and closed as and when required, due to the following reasons explained. First, rusting and subsequent swelling of the mild steel rim compresses and hardens the dust collected in the 5mm gap between the cover and frame. This makes it practically impossible to remove the cover from the frame. Second, the hooks are so positioned that the workman who is trying to remove the cover by usually available tool, i.e pickaxe, gets no leverage. In this process, sometimes the workman pulls out the hook from the cover. Common sense would dictate that the fulcrum should be obtained from an object away from the object the workman is trying to lift. Third, the m.s. hooks corrode with time and ultimately fail.Recognizing these issues, we have modified the design of the manhole cover in three areas:

In our 25 years experience of making precast concrete manhole covers and frames, we have realized that the current IS code has failed to meet some of the primary functions for which it was designed.The IS code for Heavy Duty covers provides for 2mm thick mild steel sheet around the periphery of the cover and two mild steel lifting hooks placed about 2 to 3 inches away from the extreme edge of the cover. It also provides for a gap of 5mm around the cover between the cover and the frame besides a test load of 20 MT for failure.All the above specifications except the test load have miserably failed to provide a cover which can be opened and closed as and when required, due to the following reasons explained. First, rusting and subsequent swelling of the mild steel rim compresses and hardens the dust collected in the 5mm gap between the cover and frame. This makes it practically impossible to remove the cover from the frame. Second, the hooks are so positioned that the workman who is trying to remove the cover by usually available tool, i.e pickaxe, gets no leverage. In this process, sometimes the workman pulls out the hook from the cover. Common sense would dictate that the fulcrum should be obtained from an object away from the object the workman is trying to lift. Third, the m.s. hooks corrode with time and ultimately fail.Recognizing these issues, we have modified the design of the manhole cover in three areas:

- The metal strip around the cover has been deleted, since it was not to remain for a long time anyway

- Position of the lifting hooks has been shifted to the extreme edges of the cover so that when using a pickaxe to move the cover, the frame edge automatically becomes the fulcrum

- The mild steel hooks have been HOT DIP GALVANISED to prevent rusting of hooks for a long time to come

The ultimate result of these improvements is a product that is user friendly and low maintenance.Click here to download a presentation on our new manhole cover designSpotlight Project: Jersey Barriers at Rao Tula Marg, New Delhi

21-03-2012

We have recently concluded supplying jersey barriers at Rao Tula Marg, New Delhi to permanently separate the lanes of traffic on a flyover constructed in the recent past. Below is a picture of the site.

New Product: Precast Concrete See Saw

12-10-2012

We have recently developed a see-saw for children's playground made from precast reinforced concrete. You can see some pictures below and click on the link to view a YouYube video of the same.

Case Study: Boundary wall for industrial site

12-10-2012

We are supplying and fixing precast components for construction of a 6 ft above ground height boundary wall for an industrial site located in Haryana. The wall is being built with 50 mm thick panels.

Case Study: Boundary wall for residential complex

12-10-2012

We are supplying boundary wall components for construction of a 10 ft above natural ground level boundary wall. The client required to lift the wall by upto 3 feet above natural ground level so as to leave room for filling of soil at a later stage. To accomplish this, the boundary wall poles are embedded in a PCC footing that is being cast on site.

Case Study - Precast Wall for a Residential Development

18-01-2013

We are supplying and installing 7 ft high precast concrete boundary wall for a residential project located in Bhiwadi, Rajasthan. The total length of the boundary wall is 1.75 KMs.

The wall is being constructed from 8 ft high poles which are being erected in the ground up to a depth of 2 ft. Between adjacent poles we are inserting 40 mm thick wall slabs to bring the above ground height to 7 ft. The middle panel of the wall has been customized with an engraving of the builders initials.

The total project will be completed in under 5 months.

Beautifying SDMC parks

10-05-2013

We have been awarded a tender to supply 4000 nos decorative finish chair benches across parks falling under the jurisdiction of South Delhi Municipal corporation.

The seat and back portion of these benches are being polished with commercial radial polishing machines to provide a decorative and aesthetically appealing finish.

So if you live in South/West Delhi you will be sure to see these benches enhancing the beauty of the parks and providing a comfortable place to sit and mingle with family and friends for years to come.

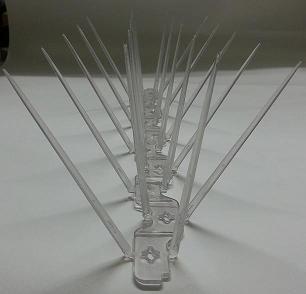

New Bird Spike Launched

13-05-2013

Hopefully, you are already familiar with our stainless steel spikes to solve bird nuisance. Now we have added an all polycarbonate spike to our offering. Polycarbonate, from which these spikes are made, is one of the toughest plastics known to mankind and finds use in making bullet proof glass.

Similar to stainless steel spikes, the polycarbonate spikes also deter birds from sitting on your property without hurting them.

In our 25 years experience of making precast concrete manhole covers and frames, we have realized that the current IS code has failed to meet some of the primary functions for which it was designed.The IS code for Heavy Duty covers provides for 2mm thick mild steel sheet around the periphery of the cover and two mild steel lifting hooks placed about 2 to 3 inches away from the extreme edge of the cover. It also provides for a gap of 5mm around the cover between the cover and the frame besides a test load of 20 MT for failure.All the above specifications except the test load have miserably failed to provide a cover which can be opened and closed as and when required, due to the following reasons explained. First, rusting and subsequent swelling of the mild steel rim compresses and hardens the dust collected in the 5mm gap between the cover and frame. This makes it practically impossible to remove the cover from the frame. Second, the hooks are so positioned that the workman who is trying to remove the cover by usually available tool, i.e pickaxe, gets no leverage. In this process, sometimes the workman pulls out the hook from the cover. Common sense would dictate that the fulcrum should be obtained from an object away from the object the workman is trying to lift. Third, the m.s. hooks corrode with time and ultimately fail.Recognizing these issues, we have modified the design of the manhole cover in three areas:

In our 25 years experience of making precast concrete manhole covers and frames, we have realized that the current IS code has failed to meet some of the primary functions for which it was designed.The IS code for Heavy Duty covers provides for 2mm thick mild steel sheet around the periphery of the cover and two mild steel lifting hooks placed about 2 to 3 inches away from the extreme edge of the cover. It also provides for a gap of 5mm around the cover between the cover and the frame besides a test load of 20 MT for failure.All the above specifications except the test load have miserably failed to provide a cover which can be opened and closed as and when required, due to the following reasons explained. First, rusting and subsequent swelling of the mild steel rim compresses and hardens the dust collected in the 5mm gap between the cover and frame. This makes it practically impossible to remove the cover from the frame. Second, the hooks are so positioned that the workman who is trying to remove the cover by usually available tool, i.e pickaxe, gets no leverage. In this process, sometimes the workman pulls out the hook from the cover. Common sense would dictate that the fulcrum should be obtained from an object away from the object the workman is trying to lift. Third, the m.s. hooks corrode with time and ultimately fail.Recognizing these issues, we have modified the design of the manhole cover in three areas: